Professor LIU Jing's team from Technical Institute of Physics and Chemistry of the Chinese Academy of Sciences has been working on liquid metals for more than 20 years. The last decade has witness the rapid development of liquid metal materials in many fields, such as soft robots, printing electronics and biomedicine etc. liquid metals possess a lot of extraordinary merits, including flowability, plasticity, biosafety, high electrical and thermal conductivity, which enable them as excellent conductive materials in stretchable electronics.

Recently, their team has successfully developed a magnetic liquid metal (Fe-EGaIn) based multifunctional electronics for remote self-healing materials, degradable electronics and thermal transfer printing. This research has been published in Advanced Science.

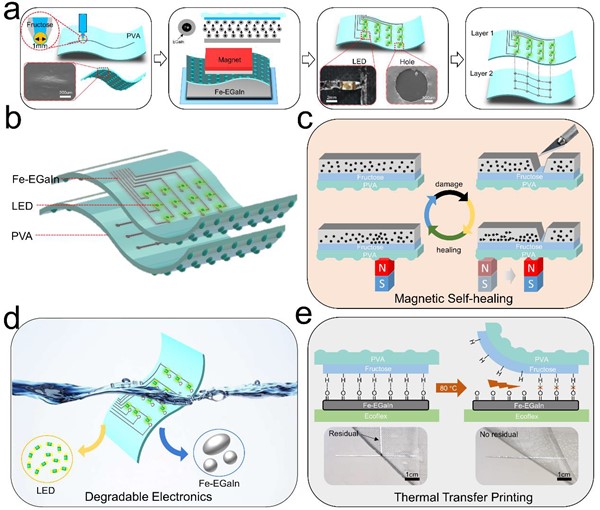

In this study, the designed multifunctional flexible electronics showed combined performances of superior remote self-healing under magnetic field, water-degradable, and thermal transfer printing, which attribute to three parts of the materials including Fe-GaIn conductive ink, degradable PVA substrate, and adhesive fructose.

A certain amount of Fe particles was mixed with gallium and indium alloy (EGaIn) to prepare magnetic liquid metal. The addition of Fe particles not only reduce the liquidity of EGaIn to enhance their plasticity and adhesive property, but also enable the magnetic regulation of the movement of the mixture in a noncontact way.

Base on the adhesive difference of liquid metal ink on various substrates, fructose was adopted to facilitate the fabrication of stable electronic circuits on PVA substrate. Under magnetic force, magnetic liquid metal ink was transfer printed on PVA film covered with fructose (Figure 1a).

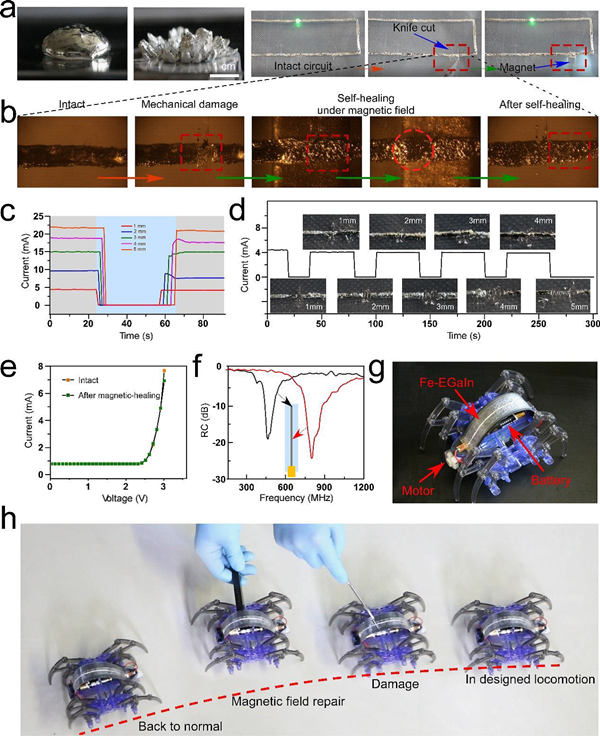

The researchers showed excellent repairing effect of a LED circuit from single or multipoint damage, reconfigurable antenna as well as the functional repairing of a moving robot (Figure 2).

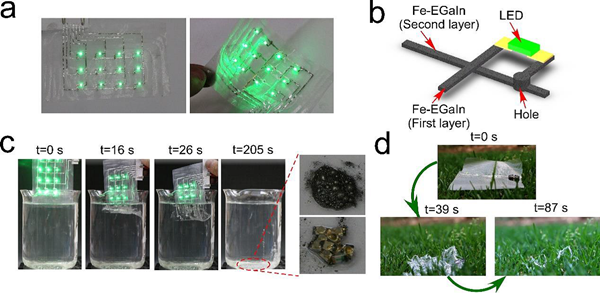

Under water circumstance, the electric circuits could be degraded and magnetic liquid metal ink could be further recycled to reduce the damage to the environment (Figure 3).

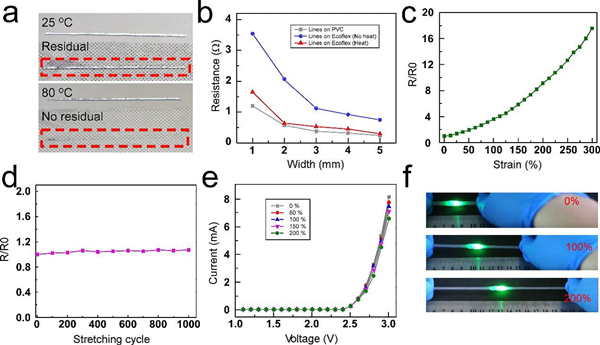

They also found that the adhesive force between Fe-EGaIn and fructose coating could be decreased in high temperature environment, which enabled enhanced transfer printing to other highly stretchable substrates, which broadens the practical applications of the present system (Figure 4).

Fig. 1. a) Preparation process of magnetic healing liquid meal electronic on PVA substrate. b) The structure of the Fe-EGaIn based electronics. c) Schematic illustration of the healing process of Fe-EGaIn electronics using magnetic field. d) Schematic illustration of the PVA/fructose enabled degradable and recyclable electronics. e) Schematic illustration of the hydrogen bond break enabled thermal transfer printing. (Image by TIPC)

Fig. 2. Fe-EGaIn enabled magnetic self-healing electronics. (Image by TIPC)

Fig. 3. PVA/fructose enabled recyclable electronics. (Image by TIPC)

Fig. 4. Fructose enabled thermal transfer printing. (Image by TIPC)

中文版

中文版