As a renewable resource rich in carbohydrates, lignocellulose has great potential in the production of green fuels, chemicals and materials. But its structure is complex, the interaction force between molecule and molecule is strong, so it is difficult to use. Therefore, it usually needs to be preprocessed before it can be utilized. At present, the pretreatment of lignocellulose has been widely studied, including physical, chemical and biological methods. However, low efficiency, poor efficiency, environmental infriendliness and unsustainability are the main challenges of biomass pretreatment. Ionic liquids, as alternative solvents for traditional organic solvents, have good solubility to lignocellulose, but their toxicity, poor biodegradability and high cost limit their industrial application. In recent years, the development and utilization of a series of low-cost, green and easy-to-synthesize ionic liquids have made it possible to industrialized the pretreatment of lignocellulose with ionic liquids. However, since most of them are hydrophilic, strong hydrogen bonds can be formed between cations and anions, which leads to their high viscosity, especially when the biomass is pretreated, the viscosity of the system increases significantly. This has a series of adverse effects on the pretreatment process and the subsequent recycling of ionic liquids.

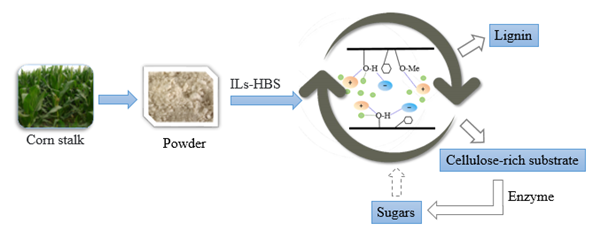

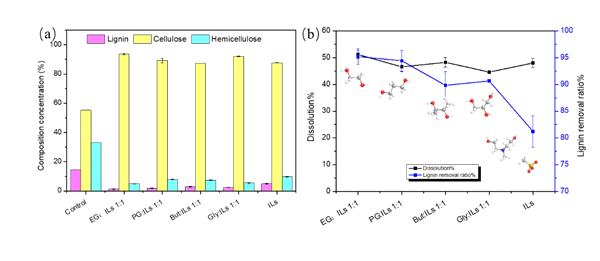

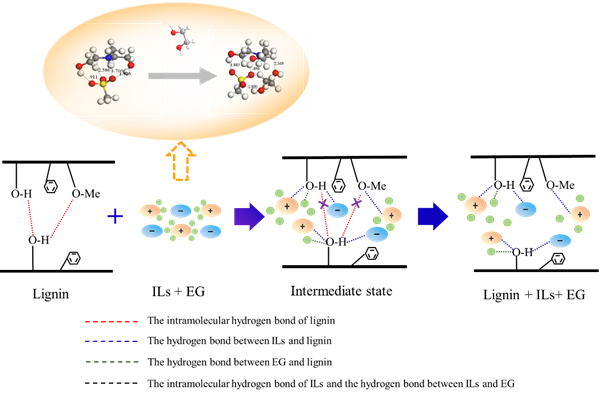

According to the Chinese Academy of Sciences Team, the number and strength of hydrogen bonds between ionic liquids and Lignin during the pretreatment of lignocellulose will influence the properties of the pretreatment, a new method was proposed to enhance the total hydrogen bond between ionic liquids and Lignin in the pretreatment system and decrease the viscosity of the system. The method (see Fig. 1) pretreated Straw by using selected high boiling alcohol as cosolvent and Proton ionic liquid. The experimental results showed that the cost and viscosity of pretreated Straw decreased after adding high boiling alcohol, at the same time, the pretreatment efficiency of ionic liquids was improved, especially the lignin removal rate (Fig. 2B) . With the decrease of alkyl chain length, the Lignin removal rate increased in the cosolvent system. Among them, ethylene glycol has the best promoting effect, which can increase the lignin removal rate from 81.2% (pure ionic liquid pretreatment) to 95.2% . On this basis, the effects of temperature, time and concentration on the selective removal of Lignin were further studied, the possible mechanism of the co-solvent system to promote the dissolution and separation of Lignin by increasing the amount and strength of total hydrogen bonds between ionic liquids and Lignin and solvent and Lignin (see Fig. 3) was proposed, that is, in the separation process of ionic liquids and solvents together with Lignin results.

In this work, a green, efficient and economical pretreatment method was adopted, which not only improved the pretreatment effect, but also solved the problems of high viscosity, difficult operation, difficult circulation and low cost in the pretreatment of Straw with ionic liquid, it provides the possibility for large-scale sustainable biomass pretreatment.

Figure 1. Flow chart of high selective lignin removal from Straw by enhancing total hydrogen bond in pretreatment system

Figure 2. A. Effects of co-solvents on the cellulose-rich Fraction; B. Effects of co-solvents on Straw dissolution rate and Lignin removal rate

Figure 3. Possible mechanism of enhancing total hydrogen bond to promote selective removal of Lignin

(Yongqing Yang, Shaoqi Yang, Xiaoqian Yao, Ying Kang, Jiayu Xin, Ibrahim El-Tantawy El-Sayed, Junli Xu and Xingmei Lu*, A renewable co-solvent promoting the selective removal of lignin by increasing the total number of hydrogen bonds, Green Chemistry, DOI: 10.1039/d0gc02319a)

中文版

中文版